GPAINNOVA to Launch Two New Surface Finishing Machines at EMO Milano 2021

GPAINNOVA, the global leader in metal surfacing by electropolishing with more than 400 customers worldwide, will be attending the next edition of EMO Milano, the world’s principal trade show for machine tools and metal, that will take place from October 4 to 9. The company will unveil there its two new machines: DLyte PRO500 Automated Cell, an equipment that allows a fully automated workpiece handling, and the latest version of DLyte 10,000, the most powerful modular unit to polish large pieces and complex geometries.

GPAINNOVA will be also showcasing at Fiera Milano the new DLyte Desktop PRO, the world’s first ultra compact dry electropolishing machine, which was launched this year. These and more electropolishing solutions, based on DLyte and MURUA systems, will be available at booth E31 (hall 5). Attendees will be able to bring their own pieces to polish them for free.

DLyte PRO500 Automated Cell: The Ultimate System for Massive Production

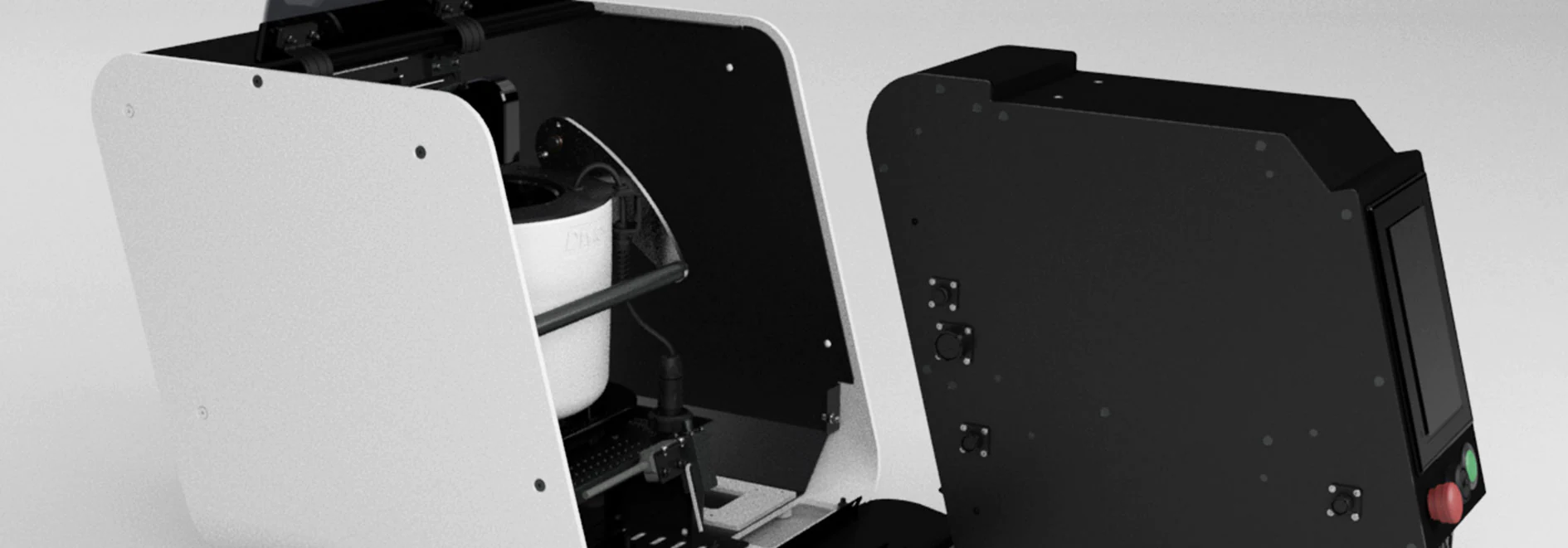

The new DLyte PRO500 Automated Cell, which is already on sale, combines one or two DLyte PRO500 machines, DLyte’s most advanced, versatile, and powerful dry electropolishing machine. DLyte PRO500 Automated Cell been equipped with a robotic arm and a rotating module that contains up to 64 pre-loaded holders with parts ready to be polished. This solution allows the system to continuously work without the need of human interaction, thus increasing productivity and safety.

This system can be used in large factories to automate the process of loading and unloading holders into and from the machine, in order to work autonomously without stopping and reducing production times.

DLyte PRO500 Automated Cell has been created with the support of the European Union’s Horizon 2020 grant for research and development of the DLyte PRO range.

DLyte 10,000: A Modular System for Large Parts and Complex Geometries

GPAINNOVA will be also showing at EMO Milano the latest version of DLyte 10,000, the modular solution designed for large industries. It has been just equipped with a robotic arm, and can be totally integrated in any production line. Compared to other existing dry-electropolishing machines, DLyte 10,000 has been designed to polish large and heavy industrial parts.

This equipment delivers totally automated, high-quality surface finishing for high-value, delicate or complex work pieces with precise and targeted finishing requirements.

To achieve the highest quality result, DLyte 10,000 combines the most advanced solutions in surface finishing with the latest technology. By combining the power of electrochemistry with a precise mechanical movement, it removes the roughness from the workpieces. It brings significant technical advantages over competing technologies such as abrasive finishing, robotic grinding and polishing, mechanical brush and grinding systems. As a results, it offers quality equivalent to manual grinding and fast and cost-effectively polishing.

The Smallest Dry Electropolishing Device on the Market

GPAINNOVA’s booth will host as well DLyte Desktop PRO, the first ultra-compact machine on the market, launched in April 2021.It has been designed to improve the work environment of all kinds of small industries by replacing the manual polishing of metal parts or with equipment that uses hazardous materials for technicians.

DLyte Desktop PRO is suitable for polishing cobalt-chrome (CoCr), titanium and stainless steel with the standard software, and additional metals with an optional software upgrade. This upgrade can treat several metals (for example, copper, brass, nickel alloys, and hard metals).

Other Surface Treatment Solutions for Industries

GPAINNOVA’s booth will host as well a DLyte 100, the largest compact dry electropolishing machine for grinding and polishing steel, stainless-steel, CoCr, nickel, titanium, carbon steel, aluminium and carbides.

Finally, GPAINNOVA will be also exhibiting MURUA, the very first desktop equipment based on passive-layer liquid electropolishing. Thanks to its advanced technology, it enables to polish precious metals —yellow, pink and white gold; palladium-coated gold, silver, copper and brass— in one step, achieving a mirror finish with a fully automated process.

Finally, GPAINNOVA will be also exhibiting MURUA, the very first desktop equipment based on passive-layer liquid electropolishing. Thanks to its advanced technology, it enables to polish precious metals —yellow, pink and white gold; palladium-coated gold, silver, copper and brass— in one step, achieving a mirror finish with a fully automated process.

GPAINNOVA to Take Part in the Speakers’ Corner

Besides presenting its suface treatment solucions, GPAINNOVA will also take part in the Speakers’ Corners organized by EMO Milano 2021. Carles Romeo, Area Sales Manager for the Spanish and the Italian markets, will deliver the short lecture «La sfida di automatizzare la finitura superficiale» («The challenge of automating surface finishing»). The conference will be held at booth B44-D31 (hall 5), on October 5 at 04.30 p.m. Anyone interested in attending this lecture can fill in this form.

About GPAINNOVA

GPAINNOVA is a technology group born in 2013 in Barcelona (Spain), with subsidiaries in Sunrise (Florida, USA), Hong Kong and Shenzhen (China), and specializing in surface metal finishing machinery, with DLyte and MURUA; medical devices with RESPIRA, Unmanned Surface Vehicles (USVs) with GPASEABOTS and high-performance power electronics with POWER INNOTECH. GPAINNOVA has a team of more than 180 professionals on staff and more than 35 engineers, and had a revenue of €15.8 million in 2020. GPAINNOVA has been selected by Financial Times among the 1,000 Europe’s Fastest Growing Companies in 2020 and 2021.

For further information:

GPAINNOVA

C/ Maracaibo, 1, naus 2-6. 08030 Barcelona

Telephone: (+34) 931 256 536